Critical Safety Measures: The Role of Gas Safe Engineers in Industrial Heating

Gas Safe engineers are pivotal in maintaining the safety and operation of industrial heating systems. You must verify their credentials, ensuring they're registered with the Gas Safe Register, to prevent risks such as carbon monoxide poisoning. These professionals conduct meticulous inspections, identify hazards like leaks, and guide on appliance maintenance. Regular checks and adherence to safety protocols are essential. Choosing a Gas Safe registered business guarantees engineers with the necessary qualifications for your heating needs. Ensuring your engineer has a valid Gas Safe ID card is crucial for compliance and overall safety. By understanding the significance of these measures, you'll navigate the complexities of industrial heating with confidence.

Understanding the Gas Safe Register

The Gas Safe Register is the UK's official list of gas engineers who are legally allowed to work on gas appliances. When you're hiring someone for gas work, whether it's for your home or an industrial setting, ensuring they're on this list is crucial. Each engineer listed has a Gas Safe ID card, which isn't just a badge of honour; it's proof of their qualification and permission to handle gas appliances safely.

Registered businesses are also a part of the Gas Safe Register, meaning they've met the necessary standards to carry out gas work. This includes installations, repairs, and maintenance of gas systems and appliances, like the Rinnai Zen- Indoor/Outdoor Combination Boiler, known for its efficiency and versatility in both residential and commercial settings.

Importance of Checking an Engineers Credentials

Before hiring a gas engineer, it's crucial to verify their Gas Safe credentials to ensure they're qualified and legally allowed to work on your appliances. Gas safety is paramount, not just for compliance but for the safety of everyone involved. When you're looking to hire a gas safe engineer, checking if an engineer is registered isn't just a step—it's your responsibility.

The Gas Safe Register is the official list of gas engineers who are legally permitted to carry out gas work. Every registered engineer carries a Gas Safe ID card, which you should ask to see. This card not only proves their identity but also lists the types of gas work they're qualified to perform.

Appliance safety hinges on the expertise of the engineer working on them. Unqualified or unregistered individuals may lack the necessary skills, putting your equipment and safety at risk. To verify an engineer's credentials, look for their registration number and check it against the database on the Gas Safe Register's website.

Ensuring the gas work carried out on your premises is done by a registered professional isn't just about adherence to regulations; it's about ensuring the longevity and safety of your gas appliances and, most importantly, the safety of all occupants.

Recognising Qualified Gas Work

Having established the importance of verifying an engineer's credentials, let's now focus on how to recognise quality gas work when you see it. First, ensure the gas engineer working on your appliances is Gas Safe registered. This means they're legally qualified for the job, reducing risks like carbon monoxide poisoning. A Gas Safe registered engineer will have an ID card with their registration number, a crucial detail to check.

Quality gas work is meticulous and adheres to safety standards. When a gas engineer is genuinely qualified, they'll conduct thorough checks and tests before and after working on gas appliances. This attention to detail is vital for ensuring the appliance's safe operation and longevity.

Moreover, a qualified gas engineer will always be willing to explain their work, offering advice on maintaining your gas appliances safely. They'll provide documentation of the work carried out, which is essential for future reference or in case of a gas emergency.

Safety Protocols for Gas Appliances

Ensuring your gas appliances adhere to strict safety protocols is crucial for preventing accidents and maintaining their efficiency. When it comes to industrial heating, the role of gas safe engineers becomes indispensable. These professionals are trained to carry out gas work following rigorous standards, ensuring that every appliance operates within safe parameters.

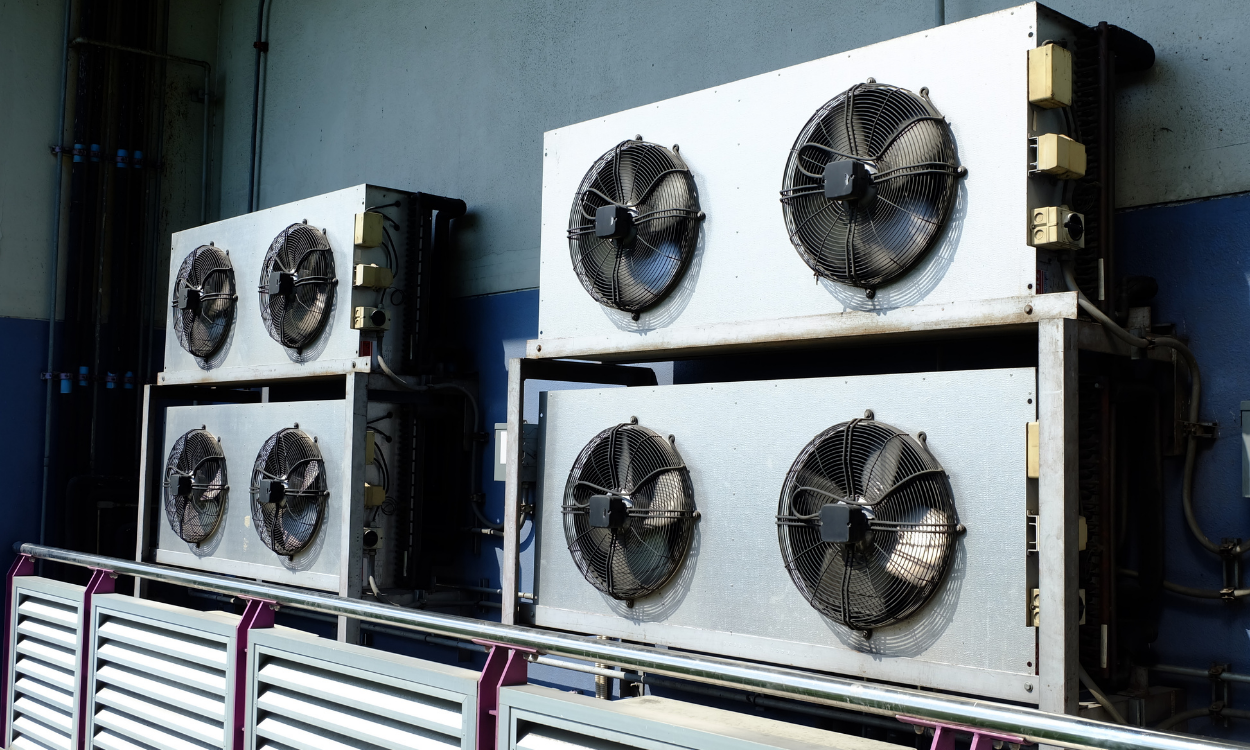

Safety protocols for gas appliances involve regular inspections and maintenance checks. Gas safe engineers are equipped to identify potential hazards, such as leaks or faulty connections, that could lead to serious accidents. Their expertise ensures that industrial heating systems, whether it's an External Condensing Gas Water Heater or an Indoor/Outdoor Combination Boiler, are installed and maintained according to the highest safety standards.

Moreover, these engineers follow a set of guidelines that dictate how gas work should be performed. This includes everything from the initial installation to routine maintenance. They're also responsible for educating users on the proper operation of gas appliances, emphasising the importance of adhering to safety protocols.

In essence, gas safe engineers play a pivotal role in ensuring that industrial heating solutions aren't just efficient but, more importantly, safe to use. Their rigorous adherence to safety protocols protects both property and lives, making them an integral part of the gas work industry.

Identifying Registered Gas Businesses

To safeguard your industrial heating needs, it's crucial to identify gas businesses that are officially registered and compliant with safety standards. When you're on the hunt to find a gas safe engineer, start by checking if the business is listed on the Gas Safe Register. This is your first step toward ensuring that any gas safety check or installation will be conducted by someone who's truly qualified for the work.

Gas safe registered businesses have engineers who carry a Gas Safe ID card. This isn't just a formality; it's a guarantee that they've the necessary qualifications to safely work on gas appliances, including specialised equipment. Each card details the types of gas work the holder is qualified to perform, providing you with peace of mind.

Before any work begins, don't hesitate to ask to see this ID card. This simple act verifies that the engineer is legally allowed to carry out gas work and ensures that your industrial heating systems are in capable hands. Remember, safety is paramount, and verifying registration is a critical step in maintaining it.

Managing Gas Emergencies Effectively

In the face of a gas emergency, it's crucial you know exactly how to respond quickly and effectively. First, recognizing the signs of a gas emergency, such as the smell of gas or a hissing sound near gas appliances, is essential. Once you've identified a potential gas emergency, it's vital to act without delay. Ensure you don't turn on lights or ignite any flames, as this could trigger an explosion. Opening windows to ventilate the area and turning off the gas supply at the meter can help mitigate risks before professional help arrives.

Contacting a professional registered with the Gas Safe Register should be your next step. These individuals have the qualification and authorisation to carry out gas work safely. They're equipped with the necessary skills to manage gas emergencies, inspect appliances for safety, and perform necessary repairs or maintenance. Always check an engineer's Gas Safe ID card to verify their credentials and ensure they're qualified to handle the specific type of gas work you need.

Conclusion

In conclusion, ensuring gas safety in your industrial heating setup is paramount, and this is where Gas Safe engineers become indispensable. By checking their credentials and ensuring they're registered, you're not just complying with regulations; you're making a critical investment in safety and efficiency.

Recognise qualified gas work and adhere to safety protocols for gas appliances. In emergencies, knowing how to respond and having the right heating solutions installed by certified professionals can make all the difference.

Always prioritise safety and quality by choosing registered gas businesses for your needs.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.

Winrow - Enquiry Form

Industrial Heating - Latest News