Maximising Efficiency: Heat Recovery Strategies for UK Warehouse Facilities

With the drive towards net-zero carbon emissions and the increasing cost of energy, warehouse and industrial facility managers across the UK are under pressure to find effective solutions for reducing energy consumption. Namely heat recovery can be defined as a range of strategies that capture and reuse waste heat. This has emerged as a cornerstone of energy efficiency for warehouses, particularly those relying on warm air heating systems. This blog explores leading Warehouse Heat Recovery strategies, their benefits, and practical considerations for implementation across the warehousing sector in the UK.

Why Heat Recovery Matters

Warehouses and large industrial buildings are notorious for their high energy demand, particularly during the colder months. It goes without saying that maintaining comfortable working conditions requires significant heating. However, much of the heat generated is lost through ventilation or rises and remains trapped at higher levels of the facility. Without intervention, this can lead to a considerable amount of wasted energy and high operational costs associated with warm air heating.

Heat recovery strategies mitigate this waste by capturing heat from sources such as exhaust air, machinery, or other processes and redirecting it to pre-heat incoming air, water, or to supplement space heating. The most efficient heat recovery systems can recover a substantial amount of waste heat; however, this can range from 60-90% on average. Subsequently, this has the potential to lower both energy bills and the amount of carbon emissions that are being emitted. This can be one way in which businesses can look towards future-proofing their operations.

Core Heat Recovery Strategies for UK Warehouses

1. Air-to-Air Heat Exchangers

Among the most widespread solutions, air-to-air heat exchangers use either plate heat exchangers or rotary wheels (also known as thermal wheels) to transfer heat from outgoing exhaust air to incoming fresh air. Generally, the two air streams pass close to each other but never mix, as heat is conducted through thin plates or rotating thermal masses. Modern units can recover 60–90% of the exhaust heat, depending on technology and installation quality. This dramatically reduces the demand on primary heating systems while ensuring fresh, comfortable air for all employees on site.

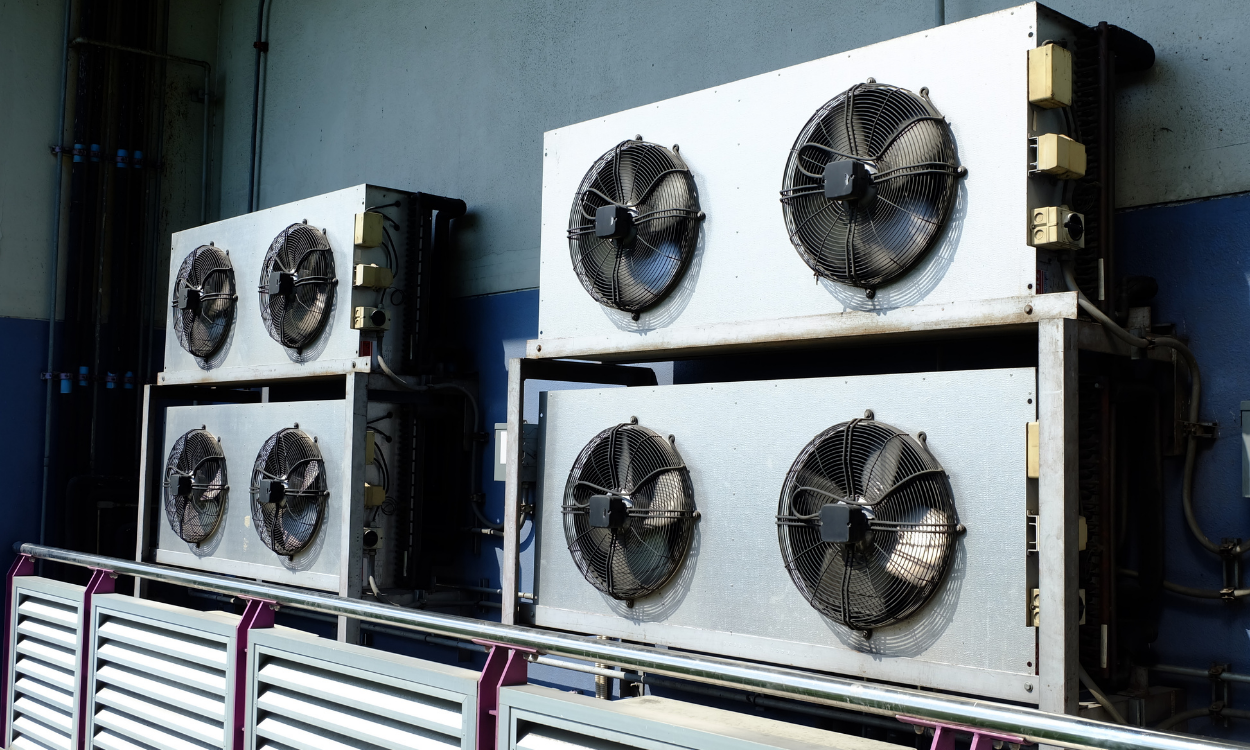

2. Compressor Heat Recovery

Compressors are ubiquitous in industrial settings, powering tools and equipment but also generating substantial amounts of waste heat. Rather than venting this heat into the atmosphere, it can be captured—either as warm air or through heat exchangers using water—to provide supplementary heating within workshops or warehouse spaces. In some facilities, compressor heat recovery can offset a significant portion of winter heating requirements and provide hot water for processes or amenities.

3. Water-Based Heat Exchangers

For warehouses with significant process heat from machinery or compressors, water-based heat exchangers can capture exhaust heat and transfer it to circulating water. This hot water can then be used for space heating via radiant panels or for process needs elsewhere in the facility. Closed-loop systems, where water continuously circulates between the heat source and the application, offer the greatest efficiency and reliability.

4. Destratification Fans

High ceilings in warehouses create a unique challenge: warm air stratifies, meaning it rises and remains trapped above the occupied zone. Destratification fans, mounted at a high level, can redistribute warm air downwards, reducing the temperature gradient between floor and ceiling. As a result, the warm air heating system is able to work more efficiently, as it is able to run less frequently to maintain the desired temperature at ground level and reduce overall energy consumption. At Winrow, we offer a range of solutions that help clients regulate heat and air quality within their facilities. Reach out today to learn more about our solutions on offer.

5. Heat Pumps

Heat pumps are increasingly being used to upgrade low-grade waste heat from processes to the higher temperatures needed for space heating. By extracting and concentrating waste heat, heat pumps can be a valuable addition to a heat recovery strategy, particularly in sites where waste heat is available at lower temperatures.

Implementation Considerations

i. Efficiency and Integration

Selecting the right heat recovery system depends on several factors, including the warehouse’s size, existing heating infrastructure, and the sources of waste heat available. High-efficiency heat exchangers and well-designed ductwork are essential to maximising the benefits. In most cases, these systems are installed on rooftops or in plant rooms, integrating with existing ventilation and heating setups.

ii. Controls and Sensors

To achieve optimal performance, modern heat recovery units are equipped with integrated controls and various sensors. Temperature sensors ensure the supply air is delivered at the right temperature for comfort and efficiency, while occupancy and CO2 sensors can modulate ventilation rates to match demand. Humidity sensors help protect against condensation and maintain healthy indoor air quality, a crucial consideration in airtight, modern facilities.

iii. Maintenance Requirements

Maintaining system performance requires regular checks of warm air heating systems in use, including their filters and heat exchangers. Blocked filters or fouled exchanger surfaces can significantly reduce efficiency and air quality. A robust maintenance schedule is essential for safeguarding energy savings, prolonging equipment lifespan and in many cases essential for ensuring any warranty is not voided.

The Bigger Picture: Sustainability and Profitability

Beyond energy savings, heat recovery systems offer broader benefits:

- Reduced Carbon Footprint: Lower energy consumption means fewer greenhouse gas emissions, aligning with environmental targets.

- Improved Indoor Air Quality: Fresh, filtered, and pre-warmed air supports healthier, more productive workplaces.

- Lower Operational Costs: Recovered heat offsets fuel use, reducing overall energy bills and reliance on fossil fuels or other fuel and energy sources.

- Regulatory Compliance: Heat recovery supports compliance with building regulations and sustainability standards increasingly demanded in new and retrofit projects.

Heat recovery strategies are essential to improving energy efficiency in warehouse facilities across the UK. By capturing and reusing waste heat whether from ventilation, compressors, or process equipment businesses can significantly reduce their energy consumption, greenhouse gas emissions, and operating costs. As technology advances and policy support grows, the case for heat recovery in warehousing is stronger than ever. For facility managers and owners, investing in heat recovery is not just a step towards compliance but a move towards long-term sustainability and profitability. Get in contact with us today at Winrow to organise a personalised site survey.

Heat recovery strategies are essential to improving energy efficiency in warehouse facilities across the UK. By capturing and reusing waste heat whether from ventilation, compressors, or process equipment businesses can significantly reduce their energy consumption, greenhouse gas emissions, and operating costs. As technology advances and policy support grows, the case for heat recovery in warehousing is stronger than ever. For facility managers and owners, investing in heat recovery is not just a step towards compliance but a move towards long-term sustainability and profitability.

Get in contact with us today at Winrow to organise a personalised site survey.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.

Winrow - Enquiry Form

Industrial Heating - Latest News