Safely Heating a Warehouse, Factory or Office

Within any working environment, safe working temperatures are extremely important. Both low and high temperatures can cause problems for you and your workers. When the temperature of the workplace is too low, whether it be an office or a warehouse, it can cause discomfort for your employees, creating a bad atmosphere meaning lowered productivity. If your workers are busy trying to keep themselves warm they aren’t properly focusing on their work. As a result they may want to wear extra clothing on top of their uniforms or work clothing which might not be in keeping with the company’s image. Wearing clothing not specifically designed for their workplace can also cause an accident and if it is bulky it may restrict their movement. Equally, if the working environment is too hot it could cause workers to feel drowsy and maybe even dehydrated. This can lead to work being un-finished or completed to a poor standard. Just as low temperatures can cause stiff joints and colds, excessive heat can cause heat stress, migraines and other issues.

What Are The Regulations?

The Health and Safety Executive recommends that the minimum safe temperature in a working environment should be between 13ºC and 16ºC. In a warehouse or factory setting where there is a lot of physical activity it is recommended that the temperature be kept at 13 ºC. Whereas in an office environment 16 ºC is more appropriate.

Although there are many problems with a working environment being too hot, as it stands there is no legal maximum safe working temperature. The guidelines in the 1992 Workplace Regulations only state that the workplace temperature should be reasonable but what that is classed as is left to the business owner. With no definitive legal ruling in place, The Trades Union Congress over the years have gathered evidence to show the effects of excessive heat in both manual and sedentary working environment. These effects consist of fainting, stress, headaches, fatigue, breathing problems and much more. Because of this they recommend that the maximum safe working temperatures should be 27 ºC for manual workers and 30 ºC for sedentary workers.

Controlling The Temperature

There are various measures that can be taken to ensure that high and low temperatures are properly controlled.

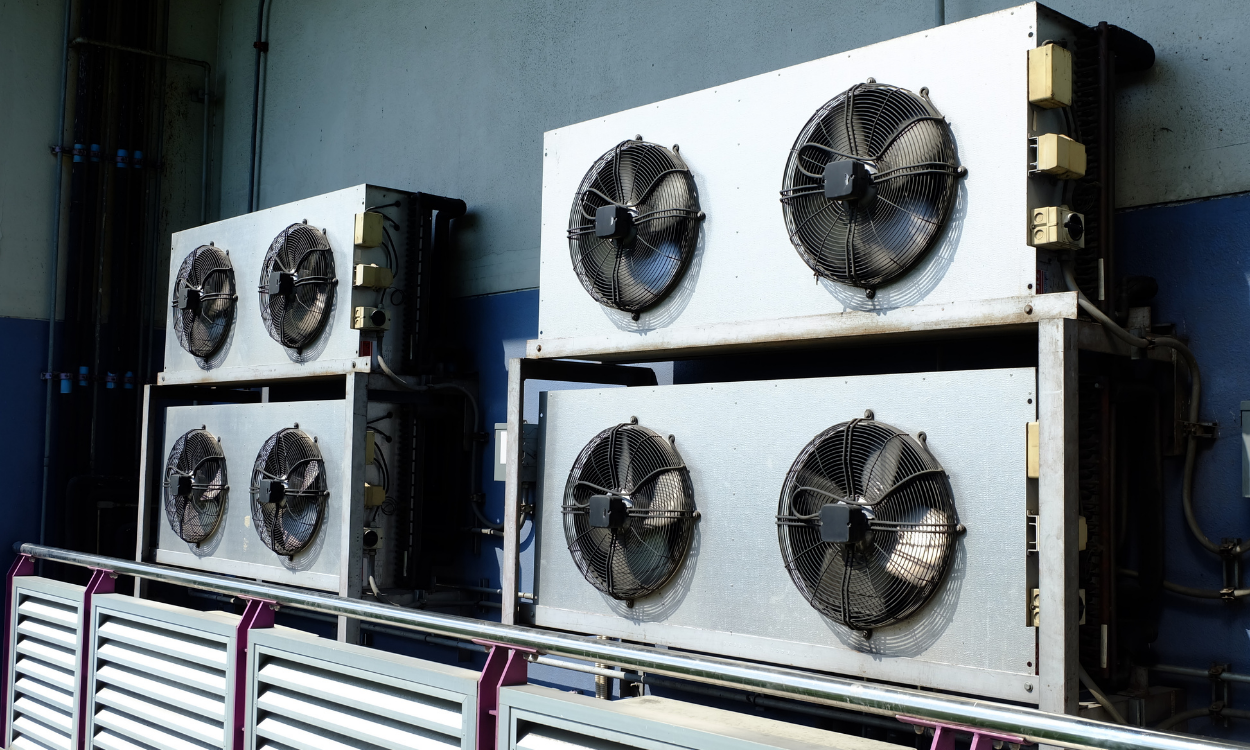

In order to control high temperatures ventilation and shades should be used in office environments to keep then environment below 30 ºC. Air conditioning can also be used in the form of open windows and fans but also through installed air conditioners. If they are installed, employers need to regularly have them checked and maintained by engineers to ensure they are working efficiently. Employers should also make sure that regular drink breaks are allowed in hotter months and that the dress code is appropriate for the change of seasons.

In terms of controlling high temperatures the measures taken are pretty standard and obvious. Employers should have safe working heaters within the working environment that are annually services and for any outdoor work, clothing to keep employees warm should be provided.

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.

Winrow - Enquiry Form

Industrial Heating - Latest News