Warm Air Heating: Advantages & Disadvantages

Creating a comfortable environment for your business is important, especially with the cold winter months approaching. One of the systems you may consider installing to keep warm is warm air heating, a method that utilises hot air being blown into a space through ductwork and vents. While this system has many advantages, there are also some disadvantages to consider before deciding if it's the right one for you. In this blog post we will discuss both the benefits and drawbacks of using warm air heating in your home so that you can make an informed decision based on your needs and budget.

What Is A Warm Air Heating Unit?

Warm air heating systems are a type of central heating system that can be used to provide warmth throughout a home. This system works by using an air delivery system, usually comprised of ducts, blower fan, and a heat source such as a furnace or heat pump. Air is heated by the heat source, then transported through the ductwork and dispersed into living spaces. The advantages of warm air heating systems include cost efficiency, low levels of maintenance, convenient operation, and improved air quality. Although these systems have benefits, they also come with some drawbacks such as the initial installation costs being expensive, large duct sizes needed for optimal performance, and lower thermal comfort due to low-velocity air movement. With proper selection and installation of this type of system, you can enjoy peaceful cozy winters in your home.

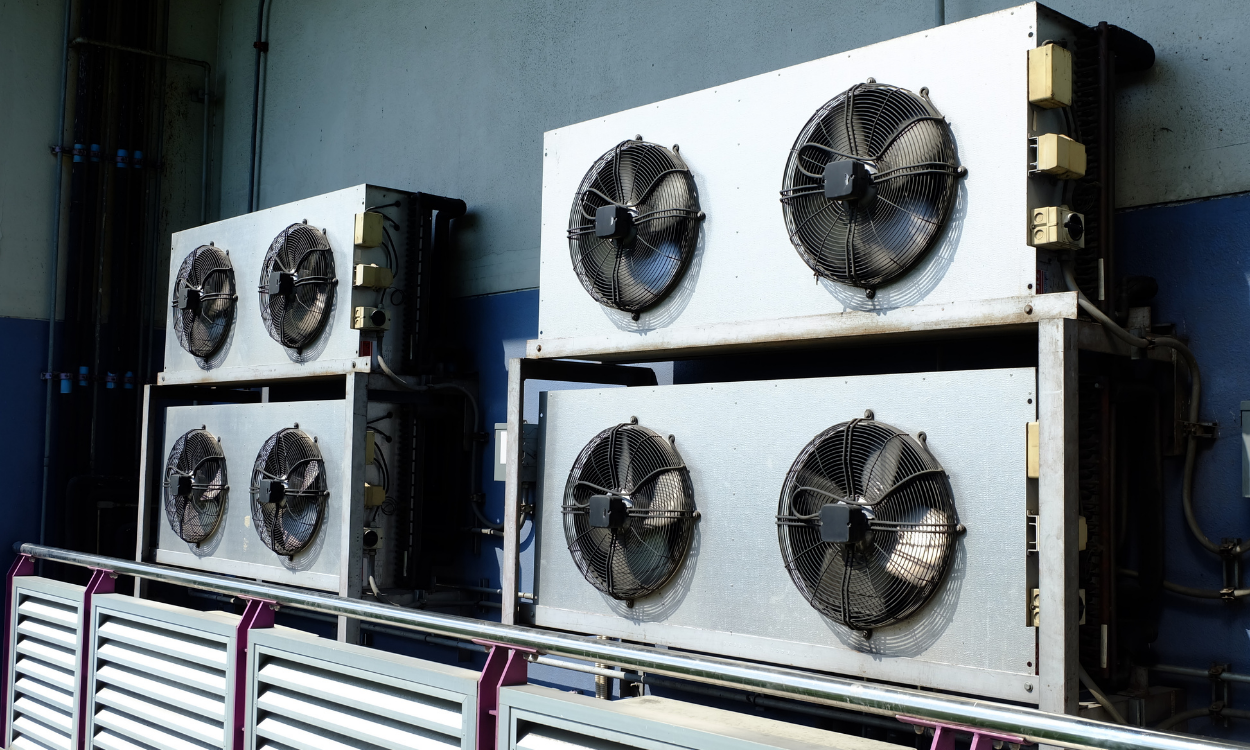

warm air heating advantages and disadvantages for warehouses and factories

As temperatures drop and as businesses shift towards digital environments, heated industrial warehouses and factories can be a huge help to keep operations running smoothly. Warm air heating (WAH) is one such system that provides efficient and cost effective ways to regulate temperature in these settings, but there are pros and cons when it comes to using this method of climate control. In this blog post, we’ll explore the advantages and disadvantages that come with using warm air heating in warehouses and factories. We’ll discuss how WAH works in these settings while also looking at common issues so you can decide whether or not this type of heat management solution is right for your business needs.

Advantages of Warm Air Heating for Warehouses and Factories

Warm air heating is becoming increasingly popular for warehouses and factories due to its numerous advantages. Unlike traditional heating systems, warm air heating can be more efficient in large commercial spaces with the ability to provide evenly distributed heat throughout the entire building. It is also an ideal choice for buildings that are prone to drafts and have large doorways because these types of systems rely on filters and fans to push warm air into isolated areas. An additional benefit to this type of system is that it can help keep airborne particles in check by running several filters throughout the building which helps maintain clean air quality. Overall, warm air heating offers a number of features that make it an attractive option for suitable commercial spaces such as warehouses and factories.

- Higher efficiency than other heating systems

One of the most impressive reasons to go with a warm-air heating system is its high level of efficiency. Compared to other systems, warm-air heating offers superior performance in terms of controlling your warehouse temperature, so that it is even and comfortable throughout. This higher efficiency also means lower energy bills in the long run, as less energy is used to maintain temperatures. Additionally, installation times for a warm-air system are typically shorter and easier than those for other systems; this helps to minimise interruption during the process and speeds up how quickly you can start reaping the benefits.

- Lower operational costs than other heating systems

Warm air heating has several advantages which make this system attractive to many warehouse or factory owners. One of the most attractive points is that it can boast the lowest operational costs among all other heating systems. This means not only will you save money right away when you switch over to warm air heating, but keeping it running won't take a toll on your pocket. It's energy efficient and there is less hassle with maintaining it than other systems, making it a great option for those looking for convenience as well as cost savings in their home heating solutions.

Disadvantages of Warm Air Heating for Warehouses and Factories

Warm air heating systems may not be the optimal choice for larger warehouses and factories, as they can put significant strain on energy bills. Additionally, warm air heating produces a less comfortable environment than other forms of heating, as drafts are more likely due to the warm air rising to ceilings quickly. Similarly, humidity levels can become imbalanced in large structures that use this type of heat source, resulting in an uncomfortable atmosphere that could impact production efficiency. Beyond comfort and running costs, warm air heating can also take up valuable floor space when roof-mounted fans are installed. When evaluating your options, therefore, it is important to consider these aspects when deciding whether or not this type of system is right for your warehouse or factory.

- Higher initial investment cost

Warming a warehouse or factory with warm-air heating can come with a higher initial investment cost than other methods, but the rewards from such an expenditure can be valuable. Warm air systems have the potential to lower long-term energy costs, reduce the time needed for maintenance, and cause fewer episodes of system breakdowns. Despite being more expensive upon installation, warm-air heating systems are often well worth it due to their long-term reliability and overall performance enhancement.

- Potential for higher humidity levels leading to condensation or even mold growth in poorly ventilated areas

In warehouse and factory settings leveraging warm air heating solutions has become an increasingly popular option due to its cost-effectiveness and ability to effectively heat large open spaces. While the advantages are significant, due to the propensity of humid air condensing on cooler surfaces, it has the potential to lead to higher humidity levels then desired in warehouse and factory areas where ventilation is not properly managed. This could result in condensation forming, potentially leading to mold growth if proper care is not taken.

- Difficulty installing ductwork in existing buildings due to limited space

Installing ductwork in existing buildings can be quite challenging, due primarily to limited space. Unfortunately, having access to a proper flow of warm air through heating is important; especially when temperatures dip below freezing during the cold winter months. Architects must find creative ways to install properly insulated ductwork that follows a clear route while minimizing disruption to the building’s occupancy. When done right, warm-air heating allows consistent temperatures across any size room and occupant comfort all throughout the year; but it all starts with an effective installation within whatever constraints can exist in an existing building's space.

Ways to Make the Most of Your Warm Air Heating System

When using a warm air heating system in warehouse or factory settings, it is important to make the most of your equipment and get the best performance for the long term. One way of doing this is to regularly maintain ventilation systems and keep filters in good condition. Additionally, positioning radiators adequately can help to maximise their efficiency and reduce energy costs while keeping even temperatures throughout warehouse or factory areas. It is also important to use thermostatically controlled heating systems that can be set appropriately to ensure optimal temperature stability at different times of the day. Finally, ensuring that correct insulation measures have been taken on external walls and making sure that windows are draught-proof can make a big difference too. These steps will help warehouse or factory owners make the most out of their warm air heating system and enjoy better results in terms of improved comfort levels as well as lower energy consumption.

- Regular maintenance and servicing of your system

For warehouse and factory owners, regular maintenance and servicing of their warm-air heating systems is an important task to ensure optimal efficiency. Not only is accident prevention a major factor, but dust, dirt and wear can all contribute to the decline of your system’s performance if not serviced correctly. However, regularly scheduling service visits can make all the difference when it comes to extending the life of your warm-air heater and saving you costs down the line. Ultimately, carrying out thorough cleaning and repairs as well as ensuring key components are working as they should can be invaluable for ensuring your warehouse or factory remains comfortable for everyone who uses it.

- Ensure adequate ventilation throughout the building

When running warehouse or factory operations, using a warm-air heating system has distinct advantages, but it is important to ensure adequate ventilation throughout the building. A well-ventilated warehouse or factory allows air to move through and around the structure, which helps better circulate air and will keep the temperature stable. Without proper ventilation, the heat can become stifling and lead to unpleasant working conditions for those who work there. It is also possible that inadequate airflow can cause problems with the heating system itself, making future maintenance more difficult. Establishing effective ventilation systems will ensure that the warm-air heating system works correctly and helps maintain comfortable temperatures in warehouse and factory environments.

- Adapt insulation practices to ensure maximum heat retention where possible

Proper insulation in warehouse or factory settings is an important factor in ensuring maximum heat retention from warm-air heating systems. Adequate insulation improves the efficiency of warm-air heating systems, saving energy and money. When warehouse or factory spaces are inadequately insulated, warm air is wasted instead of trapped, leading to higher costs associated with running the system. To get the most out of any warm-air heating system, it's essential to make sure the warehouse or factory has adequate insulation resources. Investing in some necessary upgrades and modifications can help ensure that heat produced by a warm-air system doesn't go to waste, reducing energy costs and promoting a more comfortable work environment for staff employed in warehouse or factory settings.

In summarising the advantages and disadvantages of warm air heating for warehouses and factories, we can see that it has potential to be a highly-efficient and cost-effective system. Despite some of the drawbacks in existing buildings, with proper maintenance and installation precautions taken, warm air heating can create an ideal climate for working environments where temperature control is paramount.

Lastly, it is always important to remember that even the best equipment installed in a poorly kept building will ultimately fail to serve its purpose. Therefore, utilising good insulation practices and regular monitoring of ventilation pathways will be key in unlocking your system’s optimal performance.

By investing time into researching these measures you can ensure that your warm air heating system won't let you down - no matter what kind of temperatures your factory or warehouse needs to maintain!

Share This Post.

Need a Quote?

Is your business is looking for heating upgrade or an installation quote? Please call us on 08000 588 035 for a free quotation or fill out our contact form and we’ll get back to you as soon as we can.

If you could also attach some relevant images of the building and advise the building volumetric, it will help with our initial design assessment. Thank you.

Winrow - Enquiry Form

Industrial Heating - Latest News