Our News

Radiant heat, a fundamental physics concept, is the transfer of energy through electromagnetic waves. Understanding radiant heat is key to designing efficient heating systems as it’s based on energy emission and absorption through infrared radiation. The electromagnetic spectrum, thermal radiation and blackbody radiation are the underlying principles of radiant heat . As researchers dig deeper into the science of radiant heat they uncover new applications in architecture, medicine and beyond, and pave the way for sustainable and efficient solutions that change our daily lives.

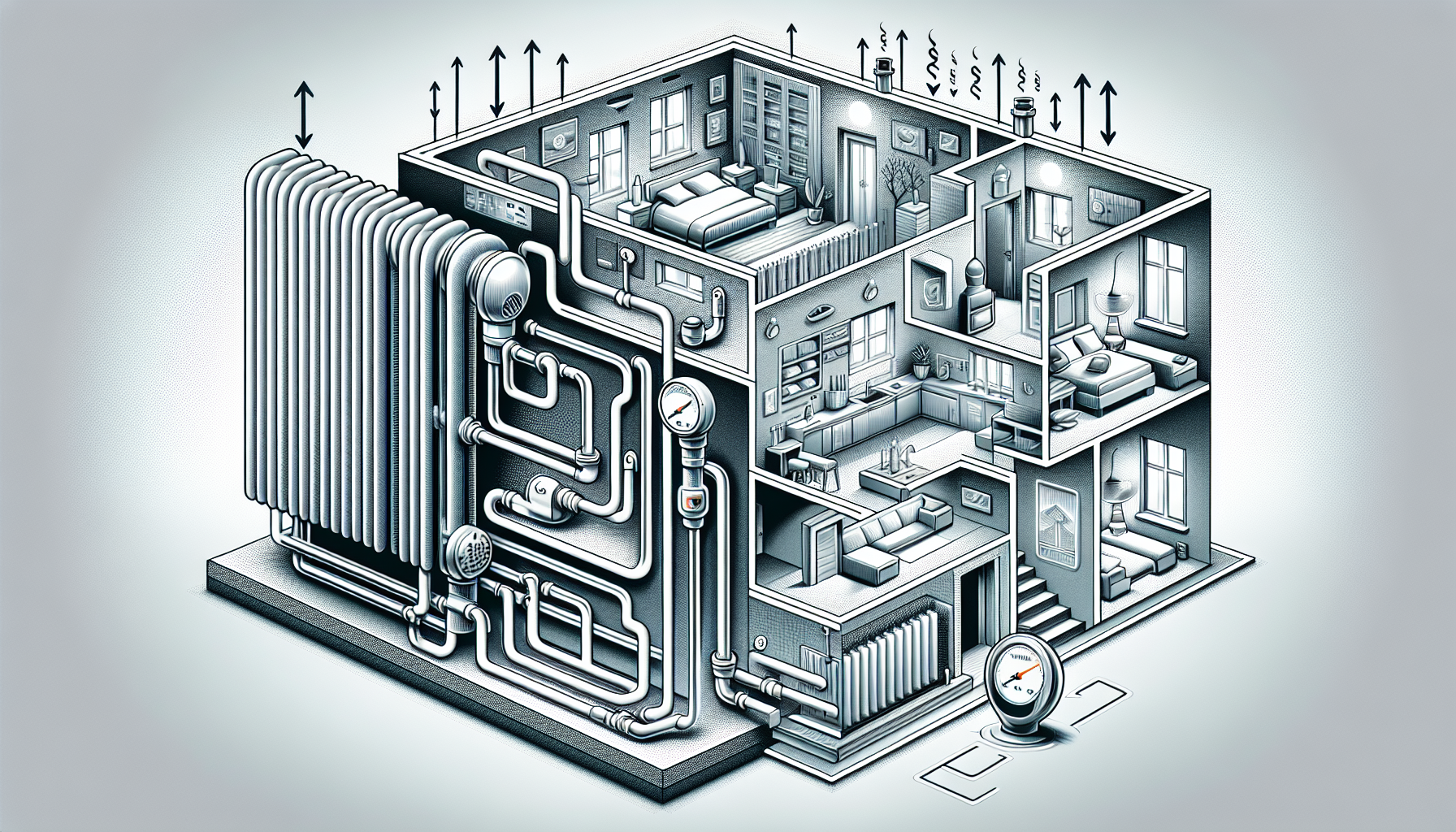

As you walk around your school do you notice uneven heating, drafty classrooms or high energy bills? These could be signs of an old heating system. You’re not alone - many schools struggle with inefficient radiators, boilers and maintenance and it’s affecting the learning environment. But what if you could provide a comfortable healthy space for your students to thrive? Modern heating solutions can make that happen. By looking into energy efficient systems and maintenance you might just find the answer to better performance and a more sustainable future for your school. Energy Efficiency When it comes to a school’s heating system you’re not just keeping pupils warm you’re also burning through a big chunk of the budget so energy efficiency is key. By doing so you’ll not only reduce energy consumption but also your school’s carbon footprint. An energy efficient heating solution can make a big difference to your school’s overall spend. For example installing modern high efficiency boilers can reduce energy waste and cut your school’s heating costs. Including energy efficient features in your school heating system can also mean long term cost savings. By investing in a reliable and efficient heating solution you’ll reduce the need for frequent repairs and replacements which can be costly and time consuming. Plus an energy efficient school heating system can create a more comfortable learning environment for your pupils so they can focus on their learning without distractions. By putting energy efficiency first you’ll be taking a big step towards a more sustainable and cost effective school heating system that benefits both your pupils and your budget. School Heating Problems Your school’s heating system has old radiators that leak, rattle or just can’t keep up with the winter months and classrooms are cold and pupils are shivering. It’s common for school heating systems to be old, inefficient and in need of an upgrade. This can mean uneven heating where some classrooms are boiling and others are freezing. You might notice your radiators are noisy, rusty or corroded which can be a sign of underlying issues. Another issue is lack of maintenance which can lead to dirt and debris building up in the system. This will reduce the overall efficiency of your school’s heating system and make it work harder and use more energy. Old boilers are also a big culprit, wasting energy and increasing your school’s energy bills. Modern Heating Solutions By installing modern heating solutions you’ll not only fix the common problems with your school’s old system but also get many benefits that improve the learning environment and reduce energy costs. A modern heating system means consistent and reliable heat distribution, a comfortable environment for pupils to focus and be productive. Energy efficient solutions like condensing boilers can reduce your school’s carbon footprint and energy bills. This means you can allocate more resources to other areas of the school. Plus modern heating solutions require less maintenance, less downtime and less disruption to the learning. And real time monitoring and control so you can optimise energy usage and spot issues before they become problems. Get in touch to find out more about how modern heating solutions can benefit your school. Boiler Maintenance Costs Regular maintenance is key to extending the life of your school’s boiler and avoiding unexpected repair costs that can mount up quickly. By doing regular checks and servicing you can spot issues before they become big problems and save your school time and money in the long run. A maintained boiler is also more energy efficient which means cost savings on your energy bills. When it comes to boiler maintenance you need to consider the cost of replacement parts, labour and downtime. On average the cost of repairing a boiler can be £500 to £2,000 or more depending on the issue. By doing regular maintenance you can avoid these repair costs and keep your heating system running smoothly and efficiently. Pupil Comfort and Health 90% of a pupil’s day is spent indoors so a comfortable and healthy classroom environment is vital for their well being and academic performance. A well maintained heating system is key to this environment. You want your pupils to be comfortable and focused not distracted by a cold or hot classroom. An old or inefficient heating system can cause a range of issues from dry air to poor air quality which can impact pupil health. And a faulty heater can cause disruption to the learning process and decreased productivity and morale. A reliable heating system means a consistent and comfortable temperature so pupils can flourish. It’s not just about physical comfort a well heated classroom can also boost pupil motivation and engagement. Condensing Gas Heaters Upgrading your school’s heating system to condensing gas heaters will benefit pupil comfort and health. Condensing gas heaters are an energy efficient solution for school heating as they capture and reuse heat that would otherwise be lost. This means big energy savings and reduced carbon emissions. You’ll see a big improvement in the warmth and comfort of your classrooms by upgrading to condensing gas heaters. When choosing a condensing gas heater consider the size of your school, number of pupils and existing heating infrastructure. Look for units with high energy ratings and low emissions. Some options include the Rinnai N1300i and N1600i internal condensing gas water heaters which have high flow rates and low energy consumption. School Heating System Design When designing a school’s heating system you need to consider the specific needs and constraints of the building including size, layout and occupancy patterns. You’ll need to think about the number of classrooms, corridors and common areas that need to be heated and the number of pupils and staff that will be using the building. This will help you determine the right size and type of heating system for your school. A well designed school heating system should provide comfortable temperatures for pupils and staff but also be energy efficient. You’ll want to look for systems that use modern low carbon technologies and have a high efficiency rating. This will reduce your school’s energy bills and carbon footprint. When it comes to choosing heating solutions consider radiators, boilers and condensing gas heaters. These will provide a reliable and efficient source of heat for your school. Also consider zoning systems that allow you to control the temperature in different areas of the building to reduce energy waste and improve overall efficiency. Why Servicing is Vital Reliability is key to a comfortable and productive learning environment and regular servicing of your school’s heating system is essential to keep it running smoothly and efficiently all year round. By servicing regularly you can identify and fix issues before they become major problems and reduce downtime and costly repairs. A well serviced heating system is not only more reliable but also more energy efficient which means big cost savings over time. Also servicing regularly can extend the life of your heating system and delay the need for expensive replacements. By keeping on top of maintenance you can ensure your school’s heating system continues to provide a comfortable and healthy learning environment for your pupils. Don’t wait until it’s too late - service your heating system today and get the benefits of a more efficient, cost effective and reliable heating system. Summary You have the power to change your school’s heating system. By choosing energy efficient solutions and regular maintenance you can create a comfortable, healthy and reliable learning environment. Don’t let old radiators and inefficient boilers hold you back. Upgrade to modern heating solutions like condensing gas heaters and get the benefits of reduced energy waste, lower carbon emissions and improved pupil performance. Take control of your school's heating system and unlock a brighter future for your students.

As you step into your retail unit, you want customers to feel at ease, don't you? The temperature plays a significant role in creating that welcoming atmosphere. If it's too cold, customers will hurry to leave, and if it's too hot, they'll feel uncomfortable. But what's the ideal temperature to keep them lingering? You're about to find out. Maintaining a consistent temperature between 20°C to 24°C (68°F to 75°F) can make all the difference in encouraging customers to stay and shop. But how do you achieve this perfect balance, and what are the benefits of getting it just right? The Importance of Retail Temperature Maintaining a consistent and ideal retail unit temperature is essential for guaranteeing the quality and safety of your products, as well as enhancing the overall shopping experience for your customers. A temperature range between 18°C to 22°C is ideal for most retail units, as it promotes a comfortable environment for customers and prevents product deterioration. To achieve this, you'll need a reliable heating system , such as the Q25SR ATAG System Boiler (25kW) or the Q38SR ATAG System Boiler (38kW), which can provide a consistent heat output. For larger retail units, the XL70 ATAG System Boiler (68.5kW) may be a more suitable option. By investing in a high-quality heating system, you can maintain that your products are stored and displayed at the perfect temperature, reducing the risk of spoilage and preserving their quality. This, in turn, will enhance the shopping experience for your customers, encouraging them to spend more time in your store and ultimately driving sales. How Cold Affects Customer Behaviour As you work to maintain that ideal retail unit temperature , you'll want to consider how a chilly environment can impact your customers' behaviour and ultimately, your bottom line. Studies have shown that customers are more likely to leave a store quickly if it's too cold, resulting in lower sales and a negative experience. In fact, research suggests that for every degree below the ideal temperature, sales can decrease by up to 2%. This is why it's vital to invest in a reliable heating system, such as the Q51SR ATAG System Boiler (51kW) or the Q60SR ATAG System Boiler (60kW), to maintain a comfortable temperature. Additionally, larger retail spaces may require more powerful boilers, such as the XL140 ATAG System Boiler (136kW), to provide consistent heat distribution. By creating a welcoming environment, you can encourage customers to linger, increasing the chances of them making a purchase. Ideal Temperature for Retail Spaces You're tasked with finding the sweet spot - a temperature that's comfortable for your customers and conducive to sales. The ideal temperature for retail spaces falls between 20°C to 24°C (68°F to 75°F). This range allows customers to feel relaxed and focused, increasing the likelihood of them making a purchase. A temperature that's too cold or too hot can be a major turnoff, leading to a decrease in sales and customer satisfaction. When it comes to maintaining the ideal temperature, having a reliable heating system is essential. For larger retail spaces, a high-capacity boiler like the XL110 ATAG System Boiler (107kW) can provide the necessary heat to keep your customers comfortable. This boiler is designed to handle large spaces and can be an ideal solution for retailers who need to maintain a consistent temperature throughout their store. Heating Systems for Large Retail Large retail spaces require powerful heating systems to maintain consistent temperatures throughout the store, and high-capacity boilers like the Q60SR ATAG System Boiler (60kW) or the XL140 ATAG System Boiler (136kW) can deliver the necessary heat to keep customers comfortable. As a retail owner, you understand the importance of maintaining a welcoming atmosphere, and a reliable heating system is vital in achieving this. A high-capacity boiler can provide the necessary heat to warm up large retail spaces , making customers feel comfortable and relaxed while shopping. When selecting a heating system for your large retail space, consider factors such as the size of the area, insulation, and the number of customers you expect to serve. A high-capacity boiler can be paired with a well-designed heating system to distribute heat evenly throughout the store. This guarantees that customers receive a consistent and comfortable shopping experience, encouraging them to stay longer and return in the future. Boiler Options for Small Retail By the time you start outfitting your small retail space, you'll need a boiler that can efficiently heat your store without breaking the bank. When it comes to boiler options for small retail, you'll want to weigh systems that provide reliable performance without excessive energy consumption. The ATAG System Boiler offers a range of models suitable for small retail spaces. The Q25SR, Q38SR, Q51SR, and Q60SR models are compact and energy-efficient, making them ideal for smaller stores. These boilers are designed to provide consistent heat while minimising energy waste. If your store requires a bit more power, the XL70, XL110, and XL140 models offer higher kW outputs without sacrificing efficiency. When selecting a boiler, bear in mind factors such as your store's size, insulation, and heating demands. Take into account that choosing a system that can meet your specific needs without overspending on energy is crucial. Energy Efficiency in Retail Heating Regularly, retailers can substantially reduce their energy bills and environmental footprint by investing in energy-efficient heating systems that optimise their store's unique temperature requirements. When it comes to retail heating, energy efficiency is essential to minimise costs and maximise comfort for customers. One way to achieve this is by installing ATAG System Boilers, which are designed to provide high-performance heating while reducing energy consumption . These boilers are available in various models, ranging from 25kW to 136kW, ensuring that retailers can find the perfect fit for their store's specific needs. By choosing an energy-efficient heating system, you can dramatically lower your energy bills and contribute to a more sustainable future. Additionally, an optimised heating system can help maintain a consistent and comfortable temperature, creating a welcoming atmosphere for your customers. Cost-Effective Heating Solutions With a range of ATAG System Boilers available, you can find a cost-effective heating solution that meets your retail unit's specific temperature requirements, without compromising on performance or efficiency. These boilers offer a variety of options to suit your unique needs, from the Q25SR (25kW) to the XL140 (136kW). Each model is designed to provide reliable and efficient heating, ensuring your customers feel comfortable and welcome in your store. When selecting a cost-effective heating solution, factor in elements such as your unit's size, insulation, and desired temperature. By choosing the right ATAG System Boiler, you can minimise energy waste and reduce your heating costs. For instance, the Q51SR (51kW) and Q60SR (60kW) models are ideal for medium-sized retail units, while the XL70 (68.5kW) and XL110 (107kW) are better suited for larger spaces . Creating a Welcoming Retail Environment You can create a welcoming retail environment by maintaining a consistent and comfortable temperature throughout your store. This is vital because it directly impacts customer experience and ultimately, your sales. A well-maintained boiler system can help you achieve this goal. By installing a reliable system boiler, you can guarantee that your store remains warm and inviting, even on the coldest days. In a retail setting, temperature plays a significant role in shaping customer behavior. When your store is too cold, customers are likely to leave quickly, reducing the chances of making a sale. On the other hand, a comfortable temperature encourages them to linger, increasing the likelihood of a purchase. By investing in a high-quality boiler system, you can create an environment that fosters customer satisfaction and loyalty.

When you're in the market for a reliable and efficient heating solution in the UK, Winterwarm heaters are definitely worth considering. You're likely drawn to their promise of energy savings and impressive performance. But before making a purchase, you'll want to know more about the range of options available, from the HR 10 to the HR 30, and what features will best suit your specific needs. What are the key benefits of their condensing warm air heaters, and how can you ensure you're getting the right fit for your space?

When it comes to electric warm air heaters , you're likely looking for a way to stay cozy while keeping your energy bills in check. But did you know that optimising your heater's performance can make all the difference? From sizing the heater correctly to strategic placement and regular maintenance, there are several key factors to bear in mind. By getting these elements right, you can substantially reduce energy waste and your carbon footprint. But what are the most effective strategies for maximising efficiency, and how can you avoid common pitfalls that might be costing you money?

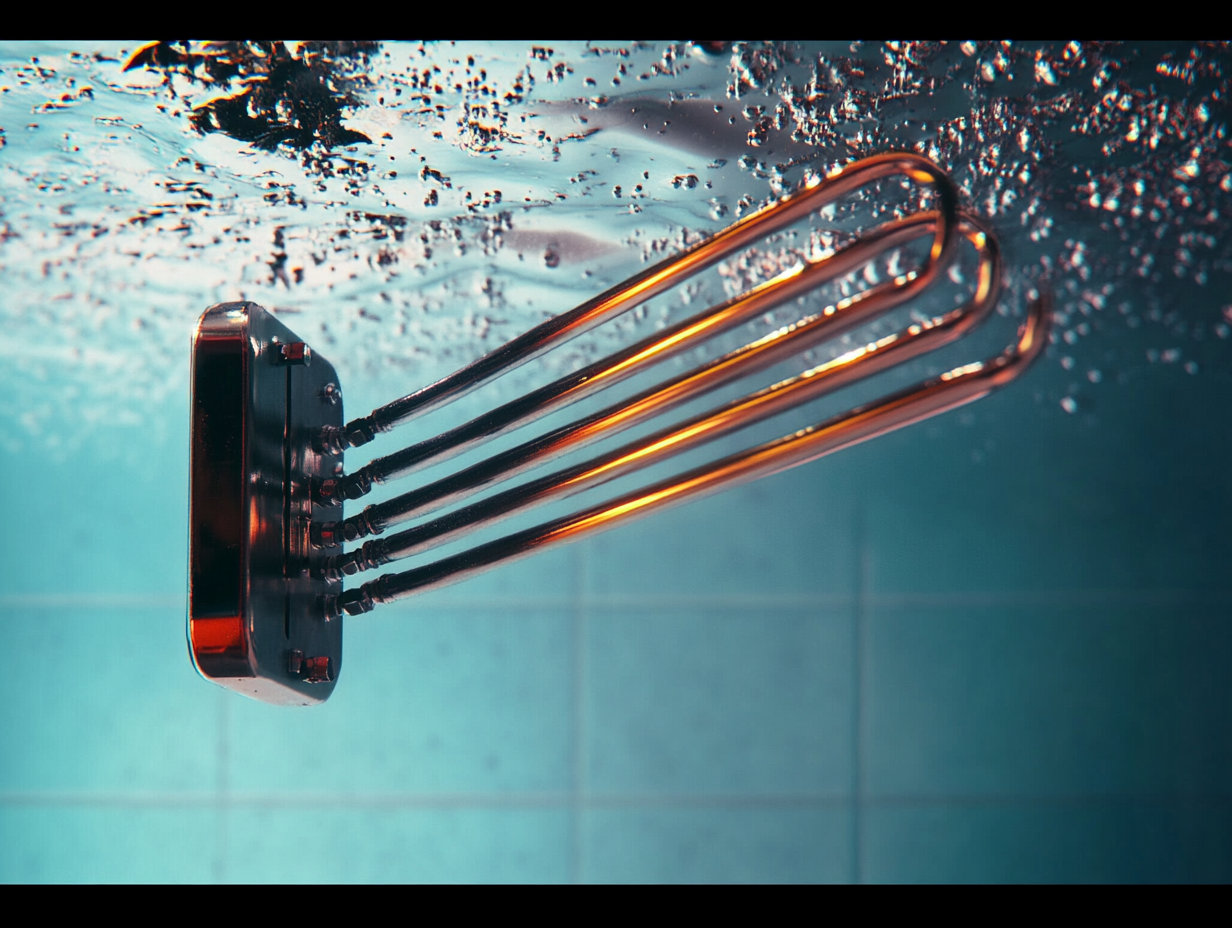

As you evaluate your retail unit's heating system, you're likely to find opportunities for improvement. Inefficient heating can lead to wasted energy, higher operating costs, and a significant carbon footprint. By taking a closer look at your current system, you'll identify areas that need attention - from outdated technology to inadequate insulation. But where do you start? Upgrading to eco-friendly solutions can be a game-changer, but what are the most effective options for your specific needs? Assessing Current Heating Systems You're likely to have an existing heating system in place, but before considering a retail unit heating solution, it's essential to assess its current performance and identify areas for improvement. This assessment will help you determine if your current shop heating system is energy efficient and meeting your retail heating needs. Take note of the system's age, condition, and maintenance history. Are there any signs of wear and tear, or have you noticed a decrease in performance over time? Are your energy bills higher than expected? These factors can indicate the need for an upgrade or replacement. Choosing Energy Efficient Options When selecting a retail unit heating solution , it's crucial to prioritise energy efficiency to minimise your environmental footprint and reduce operating costs. As a retailer, you have a significant role to play in reducing carbon emissions, and choosing energy-efficient options can make a substantial difference. Look for retail heating solutions that boast high energy efficiency ratings, such as those with condensing technology or heat recovery systems. These solutions can help you cut energy consumption by up to 30%. Additionally, consider commercial heating systems that use renewable energy sources, like biomass or solar power. Not only will you be reducing your carbon footprint, but you'll also be eligible for government incentives and tax benefits. When researching energy-efficient options, be sure to consider factors like system lifespan, maintenance costs, and overall performance. By doing so, you'll be able to make an informed decision that benefits both your business and the environment. Considerations for Gas Water Heaters As you explore energy-efficient options, it's likely that gas water heaters have caught your attention, and now it's time to weigh their benefits and limitations. You may be considering models like the Rinnai N1600E External Condensing Gas water heater (LPG & Nat Gas) (35L/Min) or the Rinnai N1300i Internal Condensing Gas water heater (LPG & Nat Gas) (26L/Min). These units offer high flow rates and low emissions, making them attractive choices for retail units. However, it's essential to consider factors like installation costs, maintenance requirements, and fuel efficiency. You'll also need to ensure that your chosen unit meets your specific hot water demands. Additionally, you might want to explore alternative options like the WWH 120 EC 20kW LPHW warm air heater with EC fan motor - Winterwarm, which can provide a different solution for your heating needs. Improving Insulation and Ventilation Six key areas in your retail unit demand attention to ensure optimal insulation and ventilation, starting with the roof and walls, then moving on to floors, windows, doors, and finally, pipework. Insulation is crucial to prevent heat loss, and you should check for gaps or cracks in these areas. Ensure that your roof and walls are well-insulated, as heat can easily escape through these areas. Floors, especially those above unheated spaces, should also be insulated to prevent heat loss. Windows and doors should be sealed properly to prevent cold air from entering and warm air from escaping. Pipework insulation is also essential, as it can reduce heat loss and energy consumption. Proper ventilation is equally important to remove stale air and moisture, which can lead to mold growth and discomfort for customers and employees. Ensure that your retail unit has a functioning ventilation system that provides a consistent flow of fresh air. Regularly clean and maintain your ventilation system to ensure it operates efficiently. Maintenance and Servicing Schedules By establishing a regular maintenance and servicing schedule, you can ensure your retail unit's heating system operates efficiently and effectively throughout the year. This includes routine checks on your heating installation, such as the Rinnai N1300E external condensing gas water heater (LPG & Nat Gas) (26L/Min), to identify potential issues before they become major problems. Regular maintenance can help prevent breakdowns, reduce energy consumption, and extend the lifespan of your heating system . It's essential to schedule annual servicing for your WWH 235 EC 28kW LPHW warm air heater with EC fan motor from Winterwarm to ensure it's running at optimal performance. During servicing, a professional technician will inspect and clean the system, check for any worn or damaged parts, and make necessary repairs or replacements. This proactive approach will help you avoid costly repairs, reduce downtime, and maintain a comfortable and safe environment for your customers and employees. Optimising Heating System Layouts You'll frequently find that optimising your retail unit's heating system layout can significantly reduce energy consumption and improve overall efficiency. This is especially crucial in industrial spaces where heating for shops can be a major energy drain. By strategically placing heating units, you can ensure that warm air is distributed evenly throughout the space, minimising hotspots and reducing the need for excessive heating. Consider the layout of your store, taking into account areas with high foot traffic, shelving units, and display cases that may obstruct airflow. By doing so, you can create a more energy-efficient heating system that meets the unique needs of your retail unit. Additionally, consider zoning your heating system, allowing you to control the temperature in different areas of the store. This can be particularly useful in spaces with varying temperature requirements, such as stockrooms or staff areas. Reducing Energy Consumption Costs Optimising your retail unit's heating system layout is just the first step; now it's time to focus on reducing energy consumption costs, which can be achieved through the strategic selection and implementation of energy-efficient heating units. One way to do this is by investing in a Rinnai N1600i internal condensing gas water heater (LPG & Nat Gas), which can provide up to 35L/min of hot water while also being energy-efficient. This type of heater is ideal for space heating and can help reduce your energy bills. Additionally, consider upgrading to energy-efficient heating units that have a high energy rating, as they can help reduce your carbon footprint and lower your energy consumption costs. By making these changes, you can create a more sustainable and cost-effective heating system for your retail unit. Selecting Suitable Heater Types When it comes to selecting a suitable heater type for your retail unit, it's essential to consider factors like space constraints, energy efficiency, and hot water demands. You'll want to choose a heater that meets your specific needs without breaking the bank or compromising on performance. For small, enclosed spaces, fan heaters are a great option. They're energy-efficient, compact, and can provide quick bursts of heat. Infrared heating is another viable option, particularly for areas with high ceilings or large open spaces. It works by emitting infrared radiation, which directly heats objects and people, reducing energy waste. Warm air heaters, on the other hand, are ideal for larger retail units with high ceilings. They can be powered by gas or electric and provide a consistent flow of warm air. Some popular models, such as the Winterwarm WWH 120 EC, offer high efficiency and low running costs. Space Planning for Efficient Heating Properly planning your retail unit's space can significantly impact the efficiency of your heating system, allowing you to make the most of your chosen heater type. When it comes to space planning for efficient heating, it's essential to consider the layout of your unit and how it can reduce heat loss. For instance, if you have an open-plan area, infrared heaters can be an effective solution as they directly warm people and objects, rather than heating the air. Additionally, if you have a large, industrial space, industrial heating solutions can be tailored to meet your specific needs. To maximise the efficiency of your heating system, consider the following tips: identify areas where heat may be escaping, such as gaps around doors or windows, and take steps to seal them. Also, think about the location of your heating units and ensure they're not obstructed by furniture or other objects. Upgrading to Eco-Friendly Solutions You can significantly reduce your retail unit's carbon footprint by switching to eco-friendly heating solutions that provide a cleaner, more sustainable alternative to traditional systems. One option is to install infrared heating systems, which use radiant heat to warm objects and people, rather than heating the air. This energy-saving technology can reduce your energy bills and minimise your environmental impact. Another solution is to install ceiling-mounted heating units, which can be powered by renewable energy sources like solar or wind power. These units are designed to be energy-efficient and can be controlled remotely to optimise their performance. By upgrading to eco-friendly heating solutions, you can't only reduce your carbon footprint but also create a more comfortable and sustainable shopping environment for your customers. Additionally, many eco-friendly heating solutions come with incentives like tax credits or rebates, making the transition even more appealing. Conclusion By following these steps, you'll be well on your way to improving retail unit heating in the UK. You'll reduce your carbon footprint, lower operating costs, and create a more comfortable shopping environment. Remember to assess your current systems, choose energy-efficient options, and prioritise proper insulation, ventilation, and maintenance. By upgrading to eco-friendly solutions and optimising your heating system, you'll reap the benefits of a more sustainable and cost-effective approach.

As you walk into a store, you're immediately hit with a sense of comfort - or discomfort. The temperature is either just right or it's not, and that can make all the difference in your shopping experience. You've likely been in stores where you felt too hot or too cold, and it affected your mood and willingness to stay. As a retailer, you want to guarantee your customers feel at ease, and that's where the right commercial heating system comes in. But which one is best for your store, and how can you provide a comfortable environment for your customers?

Step into a world where industrial spaces are transformed by the unparalleled comfort and efficiency of high-performance radiant heaters. Picture this - a large warehouse where workers no longer have to huddle around inefficient heating sources, but instead, experience consistent warmth and comfort radiating from above. As you consider the possibilities of radiant heating for your industrial applications, you'll find yourself drawn to the idea of an energy-efficient solution that provides not only warmth but also a level of control and reliability that traditional heating systems can't match. Curious to uncover how radiant heaters can revolutionise your industrial space?

When it comes to choosing a commercial water heater for your nursing home facility, you're not just selecting an appliance - you're ensuring the comfort, safety, and well-being of your residents. You need a system that can keep up with the unique demands of your facility. But with so many options available, how do you make the right choice? By evaluating key factors such as energy efficiency, recovery rate, and certification standards, you'll be well on your way to finding the perfect solution. But that's just the beginning - there's more to explore, and we're about to examine it all.

To guarantee your launderette stays hot, you need a water heater tailored for UK businesses. Rinnai commercial water heaters are your go-to, boasting up to 96% gross efficiency and a durable stainless steel heat exchanger. They feature easy integration with building management systems, enabling seamless operation and remote monitoring. The included LPG conversion kit offers flexibility, while the 13:1 turndown ratio optimises gas usage. These heaters also come with advanced temperature control, ensuring consistent performance and long-term savings. Opt for a model that matches your operational demands for efficiency and performance. Exploring these options further can illuminate how they meet your specific business needs.

Gas Safe engineers are pivotal in maintaining the safety and operation of industrial heating systems. You must verify their credentials, ensuring they're registered with the Gas Safe Register, to prevent risks such as carbon monoxide poisoning. These professionals conduct meticulous inspections, identify hazards like leaks, and guide on appliance maintenance. Regular checks and adherence to safety protocols are essential. Choosing a Gas Safe registered business guarantees engineers with the necessary qualifications for your heating needs. Ensuring your engineer has a valid Gas Safe ID card is crucial for compliance and overall safety. By understanding the significance of these measures, you'll navigate the complexities of industrial heating with confidence.

Gas Safety Certificates are essential for industrial installations. They ensure the safety of gas appliances in your workplace. These certificates are a legal requirement to keep employees safe and maintain compliance. By having them, you demonstrate a commitment to a secure work environment. Regular inspections are key to identifying hazards and ensuring your gas appliances function correctly. Ultimately, by prioritising gas safety certificates, you are safeguarding your workplace and everyone in it. Understanding the importance of these certificates can significantly benefit your industrial setup.

Are you prepared to embark on a journey through the innovative landscape of the UK's heating industry? The realm of heating technology is constantly evolving, offering a myriad of possibilities to transform the way we experience warmth and comfort in our homes. From state-of-the-art heat pumps to cutting-edge smart thermostats, the advancements in this sector are reshaping the way we think about heating. As you explore the latest trends and breakthroughs in heating technology, you'll gain valuable insights into the future of sustainable and efficient heating solutions . Stay tuned to uncover the key developments that are heating up the scene and paving the way for a more environmentally conscious and technologically advanced approach to heating in the UK.

Are you tired of your industrial space feeling as cold as an icebox in the winter? When it comes to ensuring a comfortable and efficient working environment, the right industrial heater installation service can make all the difference. But how do you find the perfect fit for your specific needs? Let's explore the key factors to consider when it comes to maximising efficiency and comfort in your industrial setting, from the importance of proper sizing to the long-term cost savings that come with professional installation.

Imagine working in a warm and inviting space, where the gentle hum of an innovative heating system ensures both comfort and efficiency. In the UK, the realm of heating technology is undergoing a remarkable transformation, offering a plethora of options to elevate your work environment. From cutting-edge heat pump advancements to sustainable, low-carbon heating solutions, the possibilities are endless. But what exactly are these innovations, and how can they revolutionise the way you experience warmth and energy efficiency in your business?

Are you tired of unexpected heating system breakdowns and the hassle of costly repairs? Taking a proactive approach to maintaining your heating system can save you time, money, and discomfort in the long run. By addressing potential issues before they escalate, you can ensure the longevity and efficiency of your heating system. But where do you begin? Let's explore the essential proactive maintenance tasks that can help you safeguard your heating system's performance and durability.

Are you aware that industrial heating accounts for approximately 70% of total industrial energy consumption? The world of industrial heaters is vast and varied, offering a multitude of options to suit your specific heating needs. From the efficiency of electric heaters to the power of gas-powered systems and the innovation of infrared solutions, the possibilities are endless. Whether you're seeking to optimise your production processes or ensure consistent temperatures in your industrial facility , understanding the different types of industrial heaters is essential. Join us as we explore the diverse landscape of industrial heating solutions and uncover the most suitable options for your operations.

Imagine walking into your industrial facility on a chilly morning, only to be greeted by the comforting warmth of an efficiently heated space. As you stand there, feeling the steady flow of warmth enveloping you, you realize the impact of a well-installed heating system. But what goes into ensuring that level of efficiency and performance? How can you guarantee that your industrial heaters are operating at their best? In this discussion, we'll explore the crucial aspects of expert installation services for industrial heaters, shedding light on the intricacies that contribute to an optimally heated environment for your industrial operations.